More than 3 years ago, I wrote a IDC Community post, “Using Robots to Curb Labor Shortage in Chinese Manufacturing” highlighting a factory in China that replaced 90% of the people in the factory with automation and robots. In that case the workforce was reduced from 650 employees down to only 60 people, those remaining were doing drastically different work than those jobs that were replaced. The jobs shifted from manual labor to oversight, maintenance, and support of the automation and robotics systems.

Today, I came across a similar story at CNBC titled: “The World’s First Humanless Warehouse Is Run Only By Robots And Is A Model For The Future“. According to the article, JD.com (the Chinese e-commerce giant) has the world’s first fully automated e-commerce warehouse in China. While both warehouses are examples of robotics and automation proliferating, the interesting thing is that they each represent a different type of industry. Using robotics and automation in manufacturing is nothing new, it has been ongoing for decades. Manufacturing organizations have been using automation and robotics technology to increase productivity and efficiency while reducing cost and improving quality.

However, for e-commerce and retail order fulfillment it has been a bit different. Handling small packages, breaking larger packages into smaller packages, and moving throughout a facility are all rather complex efforts that constrained the ability to fully automate.

Improving Robotics Brings the Automated Warehouse Closer

This has all changed rather recently. The capabilities of robotics are advancing quite rapidly and, as the CNBC article points out, are not just about the physical robots but also about the technology ecosystem that is driving innovation and new capabilities. The story highlights the improvement of controllers from the company Mujin that drive the movement of robotics. The unique aspect is that, with this particular system, the customer picks which robots to use and then the controllers drive the movements, regardless of the brand of robot. This allows for a common controller that can manipulate the movements of a variety of brands of robots within the same environment.

So, to answer the question of “could fully automated warehouses be closer than you think”, yes they are. However, this now calls out the need for organizations to think strategically about whether or not fully automated facilities makes sense. The fact is, just because something can be automated does not mean that it should be automated. The benefits of automation are well known and well documented, but the risk of full automation is not as well known.

Collaborative Robotics versus Full Automation

The fact is, robots are designed to take tasks, not jobs. Rather than full automation, what seems to work very well, and is being adopted quite rapidly, is the notion of collaborative robotics. These are robots that are designed to work alongside humans and in many cases collaboratively on the same tasks. In these instances, the robots take on certain aspects of the task that a robot is well suited to, while human workers remain in the loop completing other tasks. Doing this has shown to increase productivity, efficiency, and capacity while at the same time allowing an organization to mitigate the current labor related challenges (characteristic of many mature markets) and gain the benefits of automation.

Additionally, for many operations, the cost and complexity of full on automation is something that is out of reach. One of the drivers of collaborative mobile robots is that they provide a cost-effective approach to deploying flexible automation without disrupting an operation.

Certainly, in some economies higher levels of automation have become a necessity. China and Japan, for example, are turning to robotics and automation due to an aging and shrinking labor pool. In the United States, there is a surplus of demand for labor compared to the availability of workers to take on certain jobs. This labor challenge is especially prevalent in warehouse work and in fulfillment centers and is exacerbated during times of peak seasonal demand.

However, certain other economies face a different challenge. India, for example, does not have the same scarcity of labor as is occurring in other markets, in fact they have the opposite issue, an excess of available workers. This is not to say that automation technology isn’t valuable in this environment, just that the drivers for adoption of automation are different.

So is the Fully Automated Warehouse Closer Than We Think?

This all said, the question was whether or not the reality of the fully automated warehouse is closer than we think, and I believe that the technology exists today to deliver on this promise. However, not all facilities or markets are appropriate for this type of facility. Indeed, one of the biggest ethical and certainly economical discussions to have is the impact that this type of facility will have on the workforce in general. We are talking nearly a million people employed in warehousing and storage in the United States, according to the Bureau of Labor Statistics, and this doesn’t even consider the seasonal increase in labor as we head into the holiday seasons.

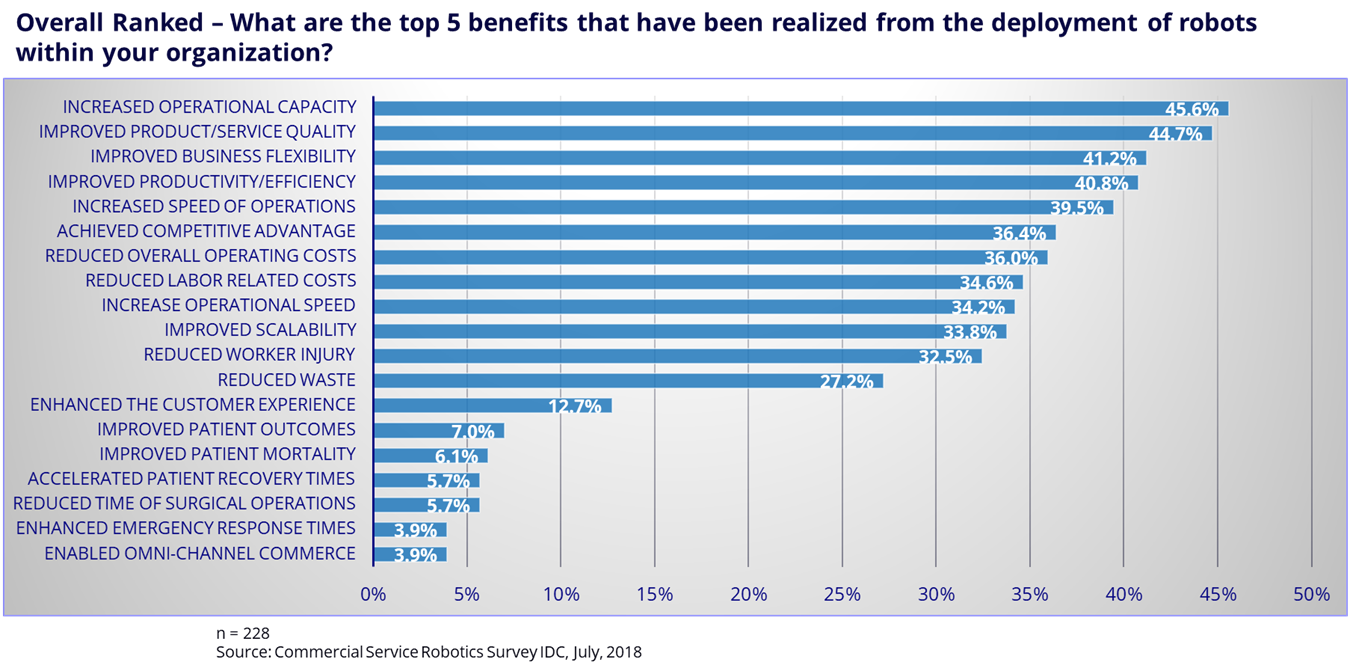

However, for those organizations that have deployed robotic technology, benefits achieved do indicate that they are aligned to the needs of the market today:

Indeed, where organizations are labor constrained today, deployments of robotics have delivered increases in capacity, flexibility, speed, and productivity.

Overall, automation technology is advancing at an incredible rate. It is about the ecosystem for automation technologies, as is evidenced by the fact that Mujin, a company making controllers, is at the center of the fully automated JD.com warehouse. As automation and robotics technologies, as well as artificial intelligence, continue to evolve, we can expect to see an increase in the number of facilities that take a fully automated approach to warehouse operations. However, even when fully automated facilities become more common, it is not likely that more manual operations will go away.

Want to learn more about how robotics improvements will continue to change and shape the way we do business? Register for IDC’s Worldwide Robotics 2019 Predictions webcast on November 20th: