Manufacturers across Asia/Pacific are navigating powerful crosscurrents: cost pressure, supply chain volatility, skills gaps, and intensifying competition. At the same time, AI is shifting from isolated pilots to systems that can plan, decide, and act. Agentic AI is moving from experimental tooling to bounded operational use cases. The shift is real, but uneven, and it will reward manufacturers that already have disciplined data, process ownership, and governance.

IDC’s FutureScape Worldwide Manufacturing 2026 Predictions for Asia/Pacific (excluding Japan) are more than forecasts. They are a planning input and a view of where investment and capability-building are likely to concentrate. Use them to pressure-test priorities and readiness, not as a certainty about what will happen or when. In the context of agentic AI, they help answer the question for leaders on whether agentic AI will matter, and how quickly they can translate these signals into measurable operating outcomes (eg. disruption recovery, cycle time, quality, OT risk).

What is Agentic AI in Manufacturing?

Agentic AI in manufacturing goes beyond analytics and copilots. It introduces AI agents that can sense conditions, evaluate options, and autonomously execute and orchestrate workflows across the organization, including planning, production, quality, engineering, IT, and cybersecurity, within defined guardrails. Humans remain accountable for strategy, oversight, and exception handling.

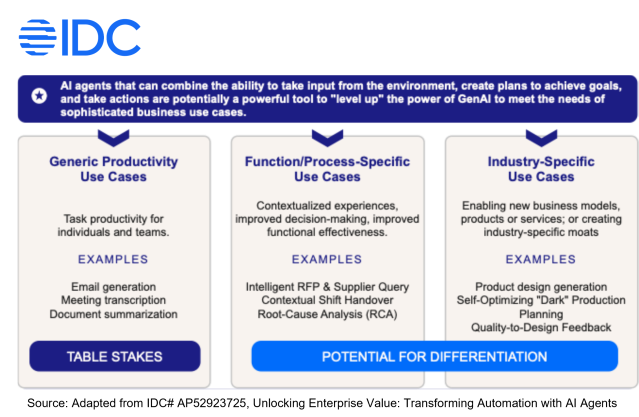

Most manufacturers in Asia/Pacific are not starting from this end state. As the differentiated use cases in the above IDC framework illustrate, many organizations remain concentrated in early stages:

- Generic productivity use cases, providing task-level assistance such as document summarization or reporting.

- Early functional or process-specific use cases where AI provides decision support within a single function but remains human-driven.

These capabilities are increasingly table stakes. They improve efficiency, but do not yet differentiate manufacturers or fundamentally change how factories, supply chains, or engineering organizations operate.

For manufacturers, the real value lies further up the curve, adopting advanced functional and industry-specific use cases, where AI agents are deeply integrated with operational data, engineering systems, and execution platforms. This is where AI begins to autonomously coordinate decisions across functions, close the loop between design and operations, and where value becomes measurable with fewer schedule resets, faster recovery, reduced security detection time, and fewer late-stage design remedies.

The following three predictions should be read through this lens. Each one highlights a step away from generic productivity toward higher-order, manufacturing-specific agentic capabilities.

Autonomous Production Scheduling

IDC Prediction: By 2027, over 40% of manufacturers with a production scheduling system in place will upgrade it with AI-driven capabilities to start enabling autonomous processes.

Autonomous production scheduling is the most pragmatic entry point into agentic AI for manufacturers because it sits at the intersection of demand, capacity, assets, labor, and supply. Most Asia/Pacific manufacturers already operate advanced planning and scheduling (APS) tools, but these systems are typically static, rule-based, and highly dependent on human planners to intervene when conditions change.

Agentic scheduling represents a step change. AI agents continuously ingest live signals from manufacturing execution systems (MES), maintenance systems, supplier updates, logistics data, and demand forecasts. They evaluate trade-offs in near real time, simulate multiple scenarios, and rebalance production plans dynamically. Over time, these agents do not just recommend changes, they begin to execute them autonomously within predefined constraints, escalating only when exceptions exceed risk thresholds.

This moves manufacturers beyond functional decision support into advanced functional autonomy. Planning is no longer a periodic activity; it becomes a continuously orchestrated process that coordinates decisions across production, maintenance, and supply chain functions.

What to do now:

- Start where volatility is highest: a constrained line, plant, or product family with frequent schedule disruption.

- Connect real-time shop floor, asset health, and supply signals directly into the scheduling layer.

- Establish human-on-the-loop governance early, then expand agent decision rights as performance, trust, and accountability mature.

Predictive Industrial Data Security

IDC Prediction: To counter data model poisoning risks, 70% of large manufacturers will use AI-enabled OT cyberdefense by 2029, autonomously flagging low-level threats and cutting detection times by 60%.

As manufacturers scale advanced agentic AI use cases, cybersecurity becomes a foundational requirement, not a supporting function. Agentic AI systems depend on trusted data, models, and execution environments. If those inputs are compromised, autonomy magnifies risk at machine speed.

AI-enabled OT cybersecurity introduces agents that continuously monitor behavior across networks, devices, control systems, and AI models themselves. Instead of relying on signature-based detection, these agents identify subtle anomalies such as data poisoning, abnormal control logic, or coordinated low-level intrusions that traditional tools and human operators often miss.

For Asia/Pacific manufacturers operating complex brownfield environments, this capability is essential to safely scaling autonomy. Without it, organizations will be forced to cap agent decision authority, limiting the very value agentic AI is meant to unlock.

What to do now:

- Map critical OT assets, data streams, and AI models that feed systems and agentic workflows.

- Deploy AI-driven anomaly detection alongside existing SOC and OT security tooling, not as a replacement.

- Define clear escalation and containment rules that balance autonomy with human accountability.

Agentic Product & Process Simulation

IDC Prediction: By 2028, 50% of A1000 manufacturers will use AI agents in conjunction with design and simulation tools to continuously validate design changes and configurations or variants against product requirements.

Continuous design validation is where agentic AI clearly enters the industry-specific tier. Today, engineering, simulation, manufacturing, and quality operate in loosely coupled stages with design validation occurring episodically, often disconnected from real-world production feedback, and issues surfacing late through defects, rework, or warranty issues.

Agentic AI changes this by embedding validation agents directly into the digital thread. These agents continuously test design changes against requirements, manufacturability constraints, historical defect data, and live production feedback. As materials, suppliers, processes, or operating conditions change, validation updates automatically, closing the loop between design intent and operational reality.

For manufacturers with high product complexity, configuration variability, or rapid innovation cycles, this capability transforms how risk, quality, and cost are managed. It shifts validation from a checkpoint activity to an always-on assurance mechanism.

What to do now:

- Integrate PLM, simulation, quality, and manufacturing data into a shared, persistent validation workflow.

- Use agents to automatically assess the downstream impact of engineering changes before release.

- Move from milestone-based validation reviews to continuous, agent-driven validation embedded in daily operations.

Turning Predictions into Action

These predictions highlight a common truth: agentic AI is not a single technology investment. It is an operating model shift. Manufacturers that succeed will align four foundations:

- Strategy: Clear ownership of where autonomy creates value, where human judgment must remain in the loop, and how decision rights evolve over time as agents mature.

- Workforce: New roles focused on supervising, governing, training, and continuously improving AI agents, not just consuming AI outputs. This includes redefining accountability as work shifts from people executing tasks to people overseeing autonomous systems.

- Technology: Modernized data, security, and cloud foundations designed for continuous orchestration, resilience, and trust spanning IT and OT environments.

- Measurement: A clear baseline of current maturity and performance, with success defined not by one-time deployments but by metrics tied to targeted outcomes, such as reduced disruption, faster cycle times, improved quality, or increased autonomous decision coverage.

For Asia/Pacific manufacturers, near-term advantage will come from moving a few bounded workflows into governed production use. Leaders who default to a “wait for certainty” strategy, delaying action until technologies, standards, or competitors fully converge, risk locking themselves into lower positions on the agentic maturity curve and find themselves under increased competitive pressure. Those who treat these predictions as navigational beacons, not distant forecasts, will build factories that are more resilient, adaptive, and competitive.

Agentic AI will not replace manufacturing excellence. It will amplify it.

FAQs on Agentic AI in Manufacturing

- What real business problems does agentic AI actually solve in factories and supply chains?

Agentic AI excels in volatile and constraint-heavy operations with frequent disruptions, competing priorities, and too many variables for humans to continuously rebalance. In practice, it helps manufacturers shorten disruption recovery time, reduce manual coordination, and ensure more decisions follow defined guardrails. Examples include autonomous production scheduling, predictive maintenance, quality inspection and predictive quality, AI-enabled OT cyberdefense, and digital twins / simulation-driven design and operations.

- Where is the ROI—quality, throughput, inventory, OEE, labor, or something else?

ROI usually shows up first as reduced disruption cost (fewer expediting cycles, fewer schedule resets, less unplanned downtime) and then as improvements in throughput and service levels once planning and execution tighten.

- Is agentic AI really different from traditional automation, RPA, or rules-based systems?

Yes, the difference is adaptive decisioning across systems, notjust automation. Rules-based automation executes what you already know; agentic AI can evaluate trade-offs under changing conditions, run scenario logic, and act within constraints, then escalate exceptions when risk thresholds are exceeded.

- What data and integration requirements matter most?

Agentic AI depends on trusted signals and tight integration across planning, shopfloor execution, asset health, and supply inputs, otherwise it just automates bad decisions faster. Prioritize master/asset data quality, event-level timestamps, and clearly governed interfaces between IT and OT, with security controls that protect both data and models, and assign data owners to ensure continued data quality assurance.

- What workforce impacts and change management issues should be expected?

Expect work to shift from “doing the task” to supervising decision quality: defining guardrails, monitoring exceptions, tuning agents, and clarifying accountability when outcomes are wrong. The hard part is decision rights, escalation paths, and aligning planners/engineers/IT/OT/security around a shared operating model, and this will involve changed responsibility and job design.

Register now for the live webinar on 24 February 2025 at 1:30 pm SGT to join IDC in charting the agentic future with confidence